All that frame work was purpose-driven, though. Having never done a frame-off restoration before (and not wanting to do ever do it again, at least on this car), I wanted everything to be clean, solid, and reasonably good-looking. I wanted the engine positioned better. I wanted to move the shocks and reinforce the frame at potential weak points.

But really, because I have a problem, I wanted to make more room for the exhaust. All that other stuff is great and I'm glad I did the work, but the underlying motivation was MORE EXHAUST. More clearance, more flow, more awesome (less noise, which is uncharacteristic, but necessary as I get older and wiser). I just love doing this stuff.

I spent a few days designing and mocking up the new pipes, making it from the headers back to the axle. I'm not sure how I'm going to do the hangers yet, so I quit there. I can't keep going with the tailpipes because I need the body back on the frame so I can see how to get around the gas tank. I could probably measure and figure it out now, but if I screw up I'll be really pissed, and I'll have to redo it under the body anyway. I may as well leave it how it is and drive it up to my dad's shop someday to do the tailpipes on his lift.

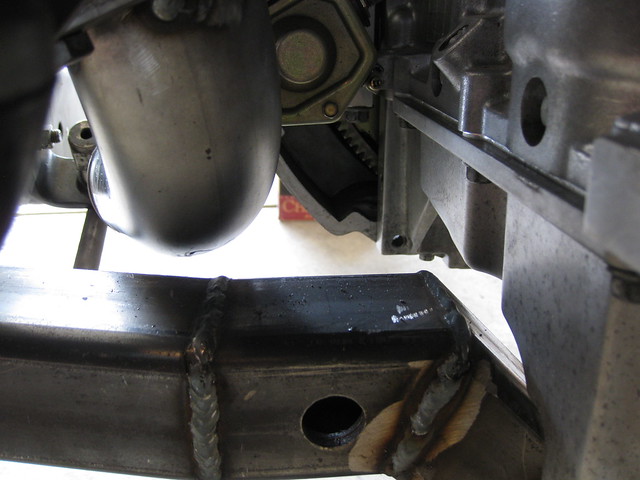

Here's how she came out.

The x-pipe is from ebay, as are the bullet-style mufflers. I think they're essentially glasspacks, although they're marketed as "resonators." I really wanted to install them after the Magnaflows, in some kind of cool cross-over arrangement behind the axle and before the gas tank (I've seen this on Mustangs before and just really like the look). However, I came to accept that 1) I have more room before the axle than after, 2) all that work would have necessitated buying more pipe bends, which are expensive, 3) the mufflers would have been really close to not only the gas tank but the lines and pump, and 4) I'm not a professional exhaust fabricator, with bending machines and lots more welding experience. I decided that the bullets will probably just act like catalytic converters and mellow out the exhaust, which is exactly what I'm after and exactly what happened on my dad's '56. We built a similar setup for him earlier this year - Moroso bullets followed by Flowmasters - and his big block is significantly quieter than before.

Pretty sweet, eh?