I need to start titling my posts better, I think. Maybe next time.

I managed to get a couple of hours in on the Ford last night. I didn't feel like getting under the car so I worked on the firewall and cowl instead. I think cleaning up the firewall might be the longest ongoing project I've undertaken with this car. Seems like I've been patching and painting it for a decade or more. Well, this time I'm trying to be patient and do it right. I'd like to check this job off the list.

Because I have nothing better to do at the moment, and because looking at pictures is the best part of reading others' car blogs, I'll include a little photo journal here.

2004

At the time, all I really cared about was getting Maude back on the road. She'd been sitting, neglected, for a few years and was looking rough. The 283 under the hood was a good little motor but what I wanted was to rebuild the 350 that was in there before. I ended up doing this, along with changing the rest of the drivetrain. Everything was shiny and new...under the hood. The rest of the car was pretty much dusted off and that's it. I did manage to quickly sand and paint the firewall and inner fenders, but as you can see I didn't even try to do any repair work.

There are holes everywhere in the firewall and cowl, and the center of the firewall, which was cut out back in 1996 to accomodate a giant HEI distributor, remains cut out (and ugly). I didn't have access to a good welder in 2004 so I didn't bother trying to patch anything. As you can imagine, an ungodly amount of heat passed from the engine compartment into the car as I was driving around, which made driving pretty miserable, even with the new engine and stuff.

2006

In 2006 I first tried my hand at sheetmetal repair, starting with the rusted out front floors. My buddy got a MIG welder and we managed to fix the floors and patch a few other holes along the way. Then I got the sound-deadening bug and spent a few months taking the interior floors and firewall down to bare metal, painting them, and putting down some dynamat and other products. I also did a bit of patching on the firewall and cowl, although with the motor installed I couldn't get much done.

2010-2012

I can't find any pictures from 2010 but I know that somewhere in there I actually patched up the big hole in the center of the firewall. I plugged a few other holes and cleaned up some wiring, but then in 2011 I lost my mind and started installing the LS1 with all of the wiring and extra stuff the EFI involves.

You can also see in the first picture where there's a huge dent in the panel right under the lip between the cowl and firewall. When I patched the hole in 2010 I did such a beautiful job that I forgot about having a distributor - not an HEI, but even my little MSD still wouldn't fit. As I recall, I couldn't put the plug wires on the cap because the firewall was too close. I also couldn't pull the distributor without pulling the motor, which is pretty inconvenient. I considered pulling the motor and redoing the firewall but at that point I just wanted the car to go (again) so I got out the hammer and smashed up my pretty sheetmetal work.

I left the dented firewall alone when I put the LS1 in there because...I wanted the car to go. By now the theme should be familiar.

I just sprayed the whole hood compartment with black rattle-can paint again and ignored the dents and holes. I figured I'd get to them another time.

2013

I got serious about the firewall late last year. I didn't plan to even touch it when I started working on the car - I was just going to "do a little work to the interior." How that snowballed is a story for another time.

Here's the car the night I pulled the body off the frame for the first time. As you can see, it's also the first time I removed the hood hinges. I was really surprised to see as much rot behind them as I did. Nowhere else on the car is or was in such bad shape...maybe the floor pans, I guess. You can see the distributor dent really well here, too.

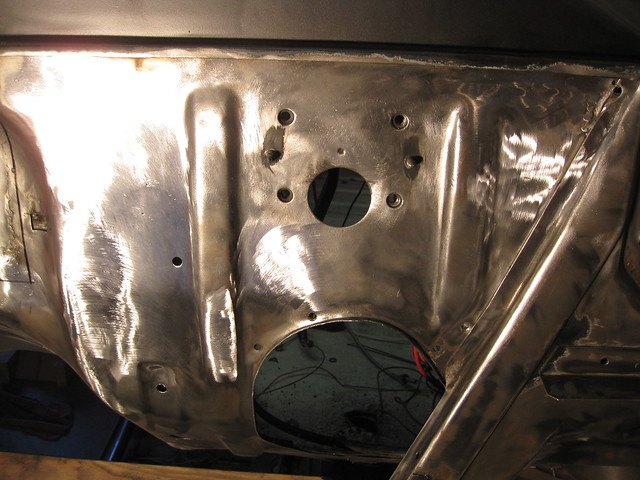

This is after a lot of wire brushing. I have a sandblaster but didn't want to use it in the garage. The wire wheel on the angle grinder worked pretty well. As I cleaned the paint off I realized my old patch job wasn't the greatest. Granted, I was new to sheetmetal repair, but my welds were pretty sloppy and I hadn't learned the magic of the flap wheel yet. I resolved to do a better job this time around. Having the right tools and a few more years of experience help a lot.

Now I'll let the pictures do the talking for a while. Obviously, I'm not a professional. However, I think the repairs are going well and I'm happy with my work. The bottom line is that I know the end results will be better than before.

That wraps up 2013. For anyone who's wondering, I don't have any special tools. I'm very fortunate to be borrowing a MIG, but other than that I just have hammers and an angle grinder. Any sheet metal bending/forming I had to do was done using random stuff in the garage for anvils or to roll bends around. It's not easy or perfect, but everything turned out pretty well.

2014

I got to the point where I needed to spray some primer and start blocking last month, but I am a big chicken when it comes to painting, and I'm great at avoidance behavior, which is why so much work suddenly got done underneath the car. But as I said, I got back to the firewall last night. The weather will be nice this weekend and I would like to have the firewall done by Sunday. Painted if possible, but at least primed if not.

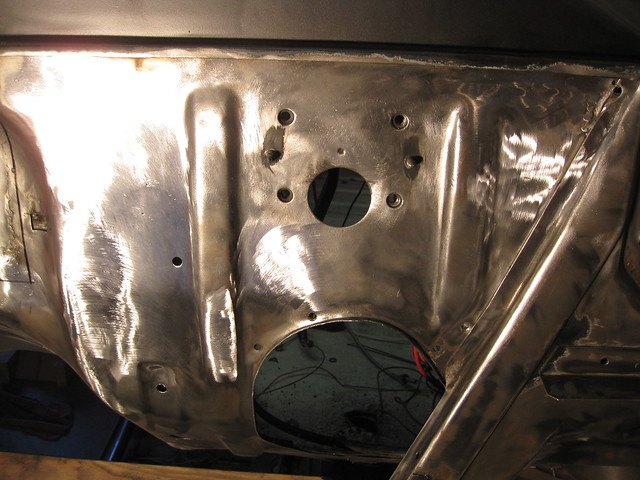

I finished cleaning off the rest of the cowl area first. Again, the wire brush was the instrument of choice. The sheetmetal is so wrinkly up there that the dremel sander and D/A are worthless. I uncovered more of my crappy repair work, which I plan to make right. I had to do a bit more welding and then I wiped everything down and spread some filler out. I wanted to continue but it got cold outside real quick last night and the filler didn't want to dry. This is how the car sits today. Hopefully I'll get more sanding/filling done tonight after work.