Remember a few posts ago when I wrote about the motor? I thought I had everything nailed down as far as engine components at that point, except my knee-jerk, impulse-buy cam selection bothered me a little. I was afraid it was too small to take advantage of the bigger heads and fancy-pants intake I ended up with (and desperately want to run). The cam was a used aftermarket truck cam and bigger in every respect than the stocker, but still nothing serious and yet had really aggressive lobe profiles that are apparently hell on the valvetrain, and noisy.

Now, it probably would have been fine, and I could have left it alone and still been happy with the performance. But of course I started shopping around for a new cam and found a killer deal on a brand-new one. Then I put the truck cam up for sale with a sort of "feeler" ad and ended up selling it and the valvesprings almost immediately, and for more than I paid for the stuff in the first place. So, I guess it was meant to be.

A new direction chosen, I tore the motor apart again. Unfortunately, removing the cam necessitated that I pull the heads, and that meant that my one-time use, stock GM head bolts that I had just installed were suddenly garbage. On the bright side, I definitely didn't do a good job cleaning out the head bolt holes the first time around, so now I could do that for peace of mind. I also picked up a new valvespring kit and a set of head studs while I was in a shopping mood.

While the heads were off again, and after I disassembled them, I got to thinking that I might try my hand at porting them. I had been watching a few youtube videos and it looked really easy. I dove into researching rotary tools and carbide bits, learning that those things are god-damned expensive but trying to convince myself that it was worth the cost. Then, as I was staring at the heads on the workbench (and, wisely, before I spent any money on porting equipment), I decided that I did a great job cleaning the outsides but really ought to do something about the insides as far as blowing all of the old carbon and crud out of the ports and chambers.

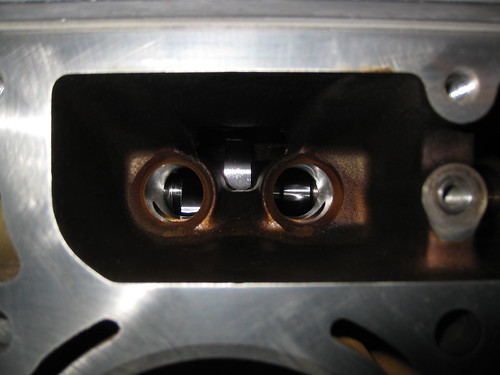

Listen guys, if you don't have a soda blaster, you should go out and buy one. Like right now. I purchased a Harbor Freight setup sometime last fall because it just happened to be on super-duper sale, but I had only recently opened it up and tried it out. I cleaned off my timing chain sprocket in a few seconds and was impressed, but it didn't really do anything on my oil pan so I gave up and put it away. Well, I fired it back up and tried it out on the cylinder heads and it worked great and fast. Check this out.

After that, I brought the heads in the house and threw them in the tub. A little scrubbing with some dish soap and they were clean and oil-free. I blew them dry with the air compressor and got to work reassembling them...again.

I knew the heads were ported when I bought them, but I couldn't really see the job because they were dirty. After soda blasting, I could make the call as far as whether to buy the expensive equipment and try some further porting. Was the existing job the best I'd ever seen? No. Was it better than I could do? Yes, without some practice, and I had no junk heads to practice on. I decided to leave them alone and focus my time and money elsewhere.

Here's the shiny new cam and the spec card. Having only ever purchased small-block Chevy cams in the past, I can't believe this one is considered "mild" with these numbers.

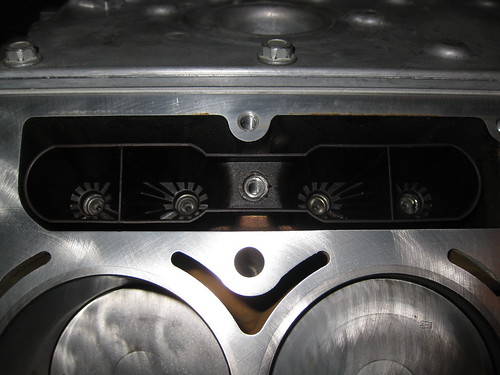

Cam's installed, time to finish up the long block. Lifters and lifter trays first, then head studs, heads, cam retaining plate, timing chain and gears, pushrods, rockers, oil pump and pickup.

That's pretty much how it looks at the moment. I stalled on putting the balancer back on because it's such a pain, then I got sick, and now we're here. I'm planning to button everything back up this weekend.

For fun, here are the FINAL specs on the motor. It's not here so I can drop names. It's for anyone who knows LS motors to have a better sense of what I'm thinking, and for anyone who wants to build an LS motor to see an example of a working, solid combo. Eventually. Probably. Hopefully...

My build

Stock 1998 Camaro 5.7L block & rotating assembly

Mildly ported 317 heads ('01-'04 6.0L truck), ~70cc chambers, ~9.75:1 compression ratio

Procomp head studs

Tick Performance cam, 221/226 duration, .608"/.605" lift, 115+2 lobe separation

Brian Tooley Racing .660" max lift dual valvesprings

Trickflow .080" wall pushrods, stock length (7.400")

Stock GM rocker arms with Comp Cams trunion upgrade

LS7 lifters

LS2 timing chain

LS6 valley cover & PCV system

Edelbrock Pro-Flo XT 90mm intake manifold

Edelbrock Pro-Flo 90mm throttle body

Edelbrock fuel rails

Summit/Earl's/Aeroquip/Russell/Fragola fuel plumbing (-6AN)

Holley valve covers

FAST ignition coils

GMPP spark plug wires

Melling standard volume oil pump

Fel-pro MLS head gaskets

No comments:

Post a Comment