I had to redo a lot of stuff in September. I didn't necessarily screw anything up before that - it just so happened that September was the time at which I had enough parts back together that I could do some final measuring. The results of this measuring indicated that I needed to make some changes or I wouldn't be able to bolt the body back onto the frame... OK, maybe I did screw up a little bit.

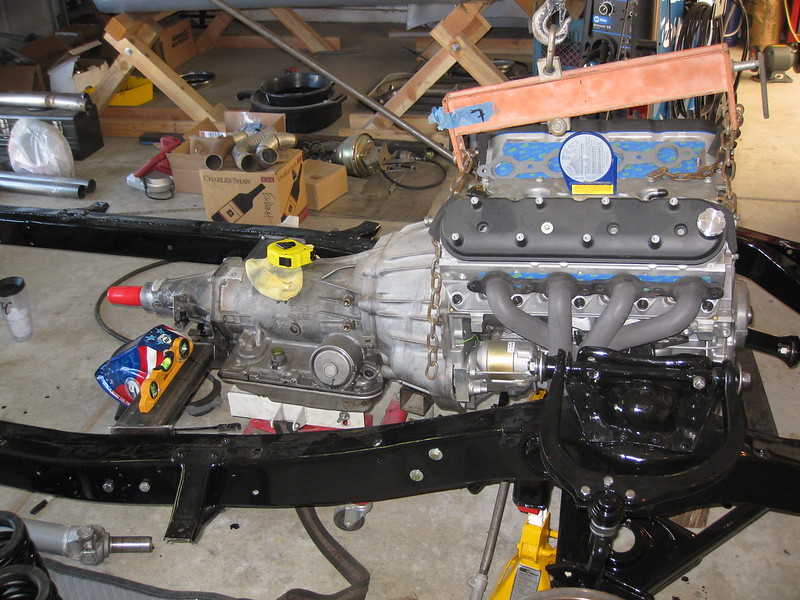

First, I put the drivetrain back in chassis. I planned to start tweaking tie rods to clear the frame and engine, but I also had to finish welding up my tranny crossmember. Most of it was done, but I purposely left the end brackets tacked in case I needed to move them down the road. Well, let's just say I'm glad I thought of that. I decided to re-check the height of the transmission case mounted in the chassis, to make sure it was still low enough to clear the body even though I had decreased the driveline angle (numerically decreased, not declined... I made it closer to horizontal). To my great surprise, something was weird. If I welded up the crossmember at that point, not only would the car body be resting on the tranny, I'm pretty sure the crossmember itself would have been touching the floor. I really don't know how that happened, but there was nothing I could do except reposition the engine and tranny. I was pretty pissed because I had already welded the perches on the rearend that set the pinion angle around 3 degrees to match the drivetrain, and I was about to change the engine angle again. But there was nothing else I could do. I played around with setting the motor lower in the chassis, leaving the angle as close to 3 degrees as possible, but it only made things worse. Either the oil pan hit the frame, or the steering hit the oil pan, or some other bad thing happened.

One small point of light in all of this gloom was when I realized that I initially positioned the motor farther backward (physically back toward the rear of the car, not leaning down) than it needed to be. I chose that position by turning the steering lock to lock and seeing where the tie rod ends on the drag link just missed the oil pan - obvious, right? Well, what I didn't consider was that I didn't have the other ends of the tie rods hooked up to anything at the time. When the steering is attached to the spindles, the steering wheel doesn't actually go all the way lock to lock. The spindles hit the lower control arm stops before the steering box runs out of play. The end result is that I found I could move the engine/tranny combo forward in the chassis about 3/4". This might not sound like much, but it was enough that I could lean the drivetrain up a little bit more before it hit the tunnel of the body, because the big-diameter parts that were first to interfere (e.g., bellhousing) were now not as close to the body. I'm suddenly thinking that a picture would help, or at least a MS Paint drawing, but unfortunately for you, I have neither. You'll just have to practice visualization.

Anyway, the bottom line is that shit needed to get moved. I cut the ends off the tranny crossmember, put the drivetrain back in the car, and measured until I found the best result. This ended up being with the drivetrain 3/4" forward as stated, angled down 4.5 degrees, and 1/4" off-center towards the driver's side. I'm concerned about the difference between the difference between the drivetrain and pinion angles, but I'm going to drive it before doing anything about it. Maybe this car won't go fast enough for any bad vibrations to occur. More than likely, I can put 2 degree shims in there and it'll be fine.

Here's the completed tranny crossmember. I rounded off the corners of the end plates mostly so I won't scratch myself working on the car in the future. It also made the whole thing slightly easier to slide into place. I had to whack about 1/2" or so off one end to move the crossmember forward in the frame as well as move it over to the side a little bit.

Why shift the drivetrain 1/4" off-center, you ask? Oh, you thought nothing else interfered when I moved everything around? That I had nothing else to redo? That's awful nice of you. Sorry friend, but the exhaust that I built a few months before was now totally screwed up.

No comments:

Post a Comment